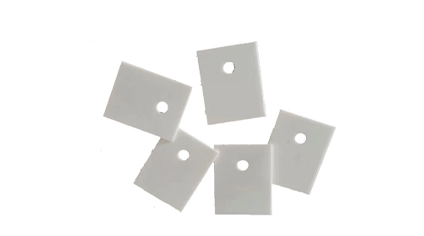

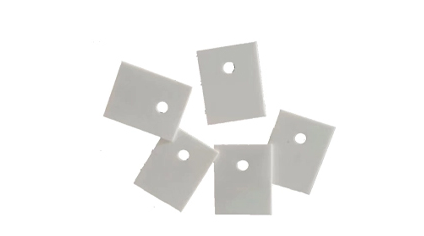

The ceramic heat sink is made of alumina heat-insulating ceramics with a high thermal conductivity of 29.3w/m.k. The product is simple in structure and small in size, but it is resistant to acid and alkali corrosion and can work under high temperatures and high pressure for a long time with stable performance. Alumina ceramics are mainly used in high-power equipment, IC MOS tubes, IGBT chip thermal insulation, high-frequency power supplies, communications, mechanical equipment, high-voltage, high-voltage, high-temperature, and other thermal insulation products.

Product features:

• Material: 96% aluminum oxide (AL 2O3) white

• Thermal conductivity: 29.3w/m.k

• Size: TO-220/3P

• Insulation below 22.5KV, temperature resistance up to 1600℃

• Density: 3.6G/CM3

• Coefficient of thermal expansion: 0.000003

• The ceramic itself does not store heat, it dissipates heat directly, and the speed is fast

• Ceramics have multi-directional heat dissipation, further speeding up heat dissipation

• Ceramic insulation, high-temperature resistance, oxidation resistance, acid and alkali resistance, long service life

• Effective anti-interference (EMI), anti-static

• Natural inorganic materials, in line with environmental protection requirements

• Small size, lightweight, high strength, save space.

• Alumina ceramic sheets are suitable for IC, MOS, triode, Schottky, IGBT and other surface heat sources that need heat dissipation!

• It is especially suitable for high-power equipment, and it is especially suitable for the design space that emphasizes lightness, thinness, shortness and smallness.

65339.43USD

65339.43USD 51.93USD

51.93USD 1.36USD

1.36USD 0.09USD

0.09USD 1874.07USD

1874.07USD 8.26USD

8.26USD 597.05USD

597.05USD 78.51USD

78.51USD 0.08USD

0.08USD 0.03USD

0.03USD 0.08USD

0.08USD

Favorites

Favorites History

History

Feedback

Feedback