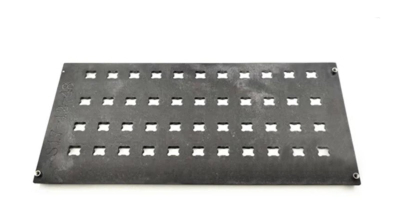

BGA Chip Bead Planting Table Solder Ball BGA Rework 90*90

Multifunctional BGA tin planting table, suitable for chip size 9~43MM. Lightweight and durable, the aluminum alloy frame structure is lightweight and durable, and the diagonal clamping design is easy to operate. The overall use of aluminum alloy is made of aluminum alloy for precise positioning, fast clamping speed, adjustable slot distance, accurate positioning, and the center of the chip.

Use tutorial:

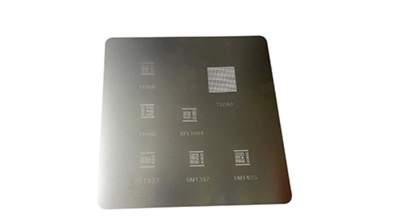

1. Align the stencil holes with the chip pads and lock the stencil screws

2. Use a small brush to dip a little BGA rework solder oil, and apply a thin layer on the BGA pad (smear a little, otherwise it will cause continuous solder balls during reflow)

3. Put the chip coated with solder oil into the ball seat and cover it (be careful not to mistake the direction of the chip)

4. Pour in the BGA solder balls

5. Gently shake the solder ball seat to make the ball stick to the chip pad, and check whether there is a leaking ball. After completion, tilt the tin planting seat to put away the solder balls, and there is a special place on the cover to place the excess solder balls

6. Check the condition of the tin balls and whether there is tin leakage. After completion, take out the chip and heat it by flow soldering, so that the solder balls and the chip pins are soldered together.

68649.09USD

68649.09USD 53.22USD

53.22USD 1.4USD

1.4USD 0.09USD

0.09USD 2016.77USD

2016.77USD 8.31USD

8.31USD 618.76USD

618.76USD 82.54USD

82.54USD 0.08USD

0.08USD 0.03USD

0.03USD 0.09USD

0.09USD

Favorites

Favorites History

History

Feedback

Feedback